Its working principle is that when the pump reaches a thermal balance, the medium inside the pump shell will no longer flow into the isolation sleeve, and the auxiliary impeller at the end of the isolation sleeve provides a high pressure to drive a circulation system at the end of the isolation sleeve. The self-circulation system of the isolation sleeve takes away the heat of the magnetic eddy current, so that the temperature of the inner rotor or medium is reduced, and the magnetic rotor will not be degaussed because the temperature of the conveying medium is too high.

The over-current parts of the thermal insulation magnetic pump are made of stainless steel 304, 316L and duplex stainless steel. High temperature heat preservation magnetic pump is suitable for petroleum, chemical industry, electroplating, environmental protection, food water treatment and other industries, mainly to transport high temperature flammable, explosive, volatile and toxic. Ideal equipment for rare precious liquids and all kinds of corrosive liquids.

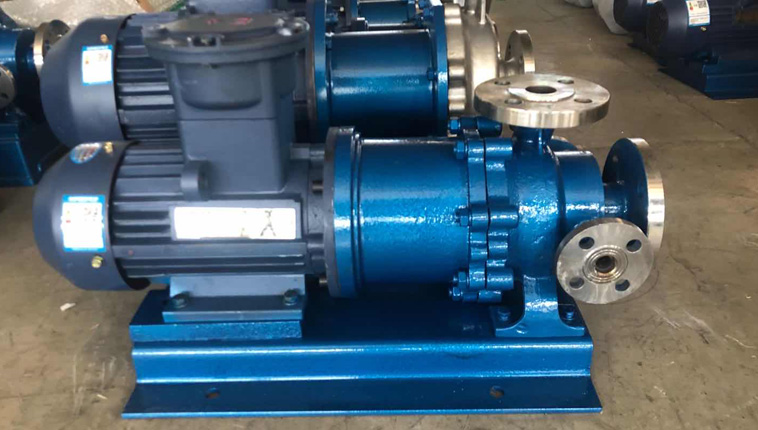

Main characteristics of high temperature magnetic pump and thermal insulation magnetic pump.

The high temperature heat preservation pump is usually composed of four parts: the water cooling device of the motor coupler and the magnetic pump, which is mainly characterized by the use of magnetic coupling to transfer power without leakage. When the motor drives the outer magnetic steel of the magnetic coupler to rotate, the magnetic force line passes through the gap and the isolation sleeve and acts on the internal magnetic steel to make the magnetic drive pump rotor rotate synchronously with the motor and transfer torque without mechanical contact. At the power input end of the pump, because the liquid is sealed in a static isolation sleeve, there is no dynamic seal, so there is no leakage. The magnetic material of the magnetic coupling uses a high temperature medium to maintain a strong magnetic torque. A water cooling device is installed between the motor and the magnetic coupling to prevent the heat of the high temperature medium from being pumped to the motor. In order to maintain the normal operation of the motor, so as to achieve non-leakage transmission of high-temperature medium.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318